- No products in the cart.

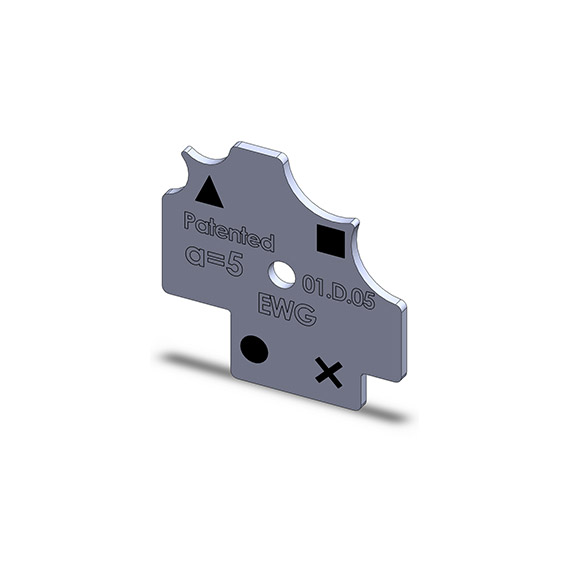

VT® SINGLE 01 > EN 1090-2:EXC1

€27,45 (HT)

Description

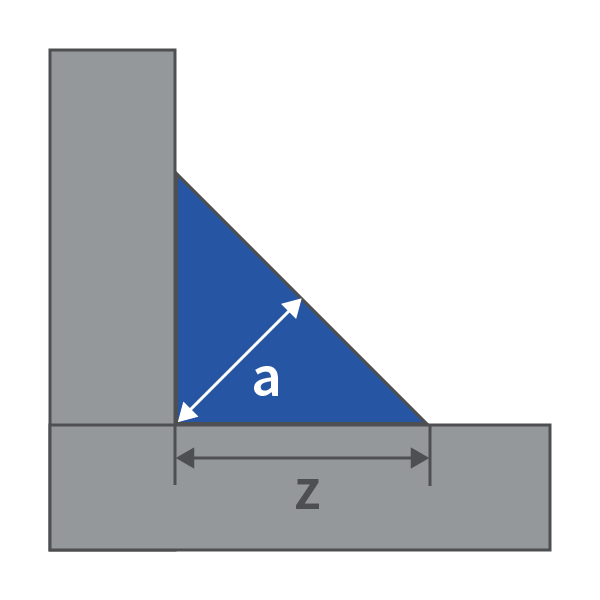

This VT® Gauge type 01 standard EN 1090-2:EXC1 allows the control of fillet welds for imperfections 512; 5213; 5214 according to the acceptance criteria of the EN 1090-2 execution class EXC1 standard. There are several sizes depending on the throat (a). The standards can be downloaded from the official ISO (International Organization for Standardization) website by clicking here.

Consider acquiring the complete VT® TOTAL kit ref. KIT.1090.EXC1

Additional information

| Archives des %%term_title%% %%page%% %%sep%% %%sitename%% | |

|---|---|

| Standard | |

| Archives des %%term_title%% %%page%% %%sep%% %%sitename%% | |

| Imperfections | |

| Configuration | |

| Type of weld |

Institut Belge de la Soudure (IBS)

The use of VT© gauges enables visual inspection by non-experts. They are suitable for all types of welding profiles and are cost-effective.

VT© gauges facilitate a visual inspection without requiring an engineering background or extensive consultation of data tables. This allows for a visual inspection to be conducted in accordance with the welding standard without the need for advanced technical skills.This streamlined inspection process is quick and efficient, eliminating past difficulties with visual inspections. Now, anyone can perform a visual quality control of welds without requiring engineering expertise. It is accessible to individuals across all professions and at an affordable price point.