| Group |

Reference |

Name |

Description |

Visual |

| 1 |

100 |

Crack |

An imperfection produced by a local rupture locale à rétat solide en arise from the effect of cooling or stresses

|

|

| 1 |

1001 |

Microcrak |

A crack only visible under the microscope |

|

| 1 |

101 |

Longitudinal crack |

A crack essentially parallel to the axis of the weld |

|

| 1 |

1011 |

Longitudinal crack |

A crack essentially parallel to the axis of the weld in the weld metal

|

|

| 1 |

1012 |

Longitudinal crack |

A crack essentially parallel to the axis of the weld

at the wetd junction

|

|

| 1 |

1013 |

Longitudinal crack |

A crack essentially parallel to the axis of the weld in the heat affected zone

|

|

| 1 |

1014 |

Longitudinal crack |

A crack essentially parallel to the axis of the weld in the parent metal

|

|

| 1 |

102 |

Transverse crack |

A crack essentially transverse to the axis of the weld |

|

| 1 |

1021 |

Transverse crack |

A crack essentially transverse to the axis of the weld in the weld metal

|

|

| 1 |

1023 |

Transverse crack |

A crack essentially transverse to the axis of the weld in the heat affected zone

|

|

| 1 |

1024 |

Transverse crack |

A crack essentially transverse to the axis of the in the parent metal

|

|

| 1 |

103 |

Radiating crack |

Cracks radiating from a common point

NOTE - Small cracks of this type are called ‘star cracks'

|

|

| 1 |

1031 |

Radiating crack |

Cracks radiating from a common point in the weld metal

|

|

| 1 |

1033 |

Radiating crack |

Cracks radiating from a common point in the heat-affected zone

|

|

| 1 |

1034 |

Radiating crack |

Cracks radiating from a common point in the parent metal

|

|

| 1 |

1045 |

Crater crack |

A crack in the crater at the end of a weld which longitudinal

|

|

| 1 |

1046 |

Crater crack |

A crack in the crater at the end of a weld which transverse

|

|

| 1 |

1047 |

Crater crack |

A crack in the crater at the end of a weld which radiating (star cracking)

|

|

| 1 |

105 |

Group of disconnected cracks |

Group of disconnected cracks in any direction |

|

| 1 |

1051 |

Group of disconnected cracks |

Group of disconnected cracks in any direction in the weld metal

|

|

| 1 |

1053 |

Group of disconnected cracks |

Group of disconnected cracks in any direction in the heat affected zone

|

|

| 1 |

1054 |

Group of disconnected cracks |

Group of disconnected cracks in any direction in the parent metal

|

|

| 1 |

106 |

Branching cracks |

A group of connected cracks originating from a common crack and distinguishable from a group of disconnected cracks (105) and from radiating cracks (103)

|

|

| 1 |

1061 |

Branching cracks |

A group of connected cracks originating from a common crack and distinguishable from a group of disconnected cracks (105) and from radiating cracks (103) in the weld metal

|

|

| 1 |

1063 |

Branching cracks |

A group of connected cracks originating from a common crack and distinguishable from a group of disconnected cracks (105) and from radiating cracks (103) in the heat affected zone

|

|

| 1 |

1064 |

Branching cracks |

A group of connected cracks originating from a common crack and distinguishable from a group of disconnected cracks (105) and from radiating cracks (103) in the parent metal

|

|

| 2 |

200 |

Cavity |

Cavity |

|

| 2 |

2011 |

Gas pore |

A gas cavity of essentially spherical form |

|

| 2 |

2012 |

Uniformly distibruted porosity |

A number of gas pores distributed in a substantially uniform manner throughout the weld metal; not to be confused with linear porosity (2014) and clustered porosity (2013)

|

|

| 2 |

2013 |

Clustered (localized) porosity |

A group of gas pores having a random geometric distribution |

|

| 2 |

2014 |

Linear porosity |

A row of gas pores situated parallel to the axis of the weld

|

|

| 2 |

2015 |

Elongated cavity |

A large non-spherical cavity with its major dimension approximately parallel to the axis of the weld

|

|

| 2 |

2016 |

Worm-hole |

A tubular cavity in weld metal caused by release of gas. The shape and position of worm-holes are determined by the mode of solidification and the sources of the gas. Generally they are grouped in clusters and distributed in a herringbone formation. Sorne worm-holes may break the surface of the weld

|

|

| 2 |

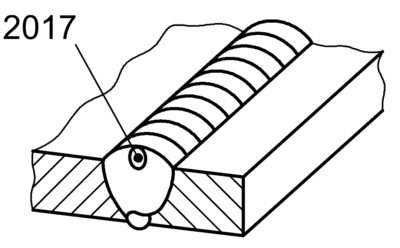

2017 |

Surface pore |

A gas pore which breaks the surface of the weld |

|

| 2 |

2018 |

Surface porosity |

Porosity appearing at the surface of the weld; single or multiple gas cavities that break the surface of the weld

|

|

| 2 |

2021 |

Interdendritic shrinkage |

Elongated shrinkage cavity that can contain entrapped gas, formed between dendrites during cooling. Such an imperfection is generally found perpendicular to the weld face

|

|

| 2 |

2024 |

Crater pipe |

Shrinkage cavity at the end of a weld run and not eliminated before or during subsequent weld runs

|

|

| 2 |

2025 |

End crater pipe |

Open crater with a hole reducing the cross-section of the weld

|

|

| 2 |

203 |

Micro-shrinkage |

Shrinkage cavity visible only under the microscope |

|

| 2 |

2031 |

Interdendritic microshrinkage |

Elongated micro-shrinkage formed between dendrites during cooling following the boundaries of grains

|

|

| 2 |

2032 |

Transgranular microshrinkage |

Elongated micro-shrinkage cavity crossing grains during solidification

|

|

| 3 |

300 |

Solid inclusions |

Solid foreign substances entrapped in the weld metal |

|

| 3 |

3011 |

Slag inclusion |

Solid inclusion in the form of slag linear |

|

| 3 |

3012 |

Slag inclusion |

Solid inclusion in the form of slag isolated |

|

| 3 |

3013 |

Slag inclusion |

Solid inclusion in the form of slag clustered |

|

| 3 |

3021 |

Flux inclusion |

Solid inclusion in the form of flux linear

|

|

| 3 |

3022 |

Flux inclusion |

Solid inclusion in the form of flux isolated |

|

| 3 |

3023 |

Flux inclusion |

Solid inclusion in the form of flux clustered |

|

| 3 |

3031 |

Oxide inclusion |

Solid inclusion in the form of oxide linear |

|

| 3 |

3032 |

Oxide inclusion |

Solid inclusion in the form of oxide isolated |

|

| 3 |

3033 |

Oxide inclusion |

Solid inclusion in the form of oxide clustered |

|

| 3 |

3034 |

Puckering |

In certain cases, especially in aluminium alloys, gross oxide film enfoldment can occur due to a combination of unsatisfactory protection from atmospheric contamination and turbulence in the weld pool

|

|

| 3 |

3041 |

Metal inclusion |

Solid inclusion of tungsten |

|

| 3 |

3042 |

Metal inclusion |

Solid inclusion of copper |

|

| 3 |

3043 |

Metal inclusion |

Solid inclusion of other metal |

|

| 4 |

400 |

Lack of fusion and penetration |

Lack of fusion and penetration |

|

| 4 |

4011 |

Lack of fusion |

Lack of side-wall fusion |

|

| 4 |

4012 |

Lack of fusion |

Lack of inter-run fusion

|

|

| 4 |

4013 |

Lack of fusion |

Lack of root fusion |

|

| 4 |

4014 |

Lack of fusion |

Micro-lack of fusion |

|

| 4 |

402 |

Incomplete penetration (lack of penetration) |

Difference between the actual and the nominal penetration

|

|

| 4 |

4021 |

Incomplete root penetration |

One or both fusion faces of the root are not melted |

|

| 4 |

403 |

Spiking |

Extremely non-uniform penetration occurring in electron-beam and laser welding giving a sawtooth appearance. This can include cavities, cracks, shrinkages, etc

|

|

| 5 |

500 |

Imperfect shape |

Imperfect shape of the external surfaces of the weld or defective joint geometry

|

|

| 5 |

5011 |

continuous undercut |

Undercut of significant length without interruption |

|

| 5 |

5012 |

Intermittent undercut |

Short length of undercut, intermittent along the weld

|

|

| 5 |

5013 |

Shrinkage grooves |

Undercuts visible on each side of the root run |

|

| 5 |

5014 |

Inter-run undercut (interpass undercut) |

Undercut in the longitudinal direction between weld runs

|

|

| 5 |

5015 |

Local intermittent undercut |

Short undercuts, irregularly spaced, on the side or on the surface of the weld runs

|

|

| 5 |

502 |

Excess weld metal |

Reinforcement of the butt weld on the face is too large

|

|

| 5 |

503 |

Excessive convexity |

Reinforcement of the fillet is too large |

|

| 5 |

5041 |

Local excessive penetration |

Reinforcement of the butt weld on the root side is too large : local excessive penetration

|

|

| 5 |

5042 |

Continuous excessive penetration |

Reinforcement of the butt weld on the root side is too large : continuous excessive penetration

|

|

| 5 |

5043 |

Excessive melt-through |

Reinforcement of the butt weld on the root side is too large : excessive melt-through

|

|

| 5 |

5051 |

Incorrect weld toe angle |

Too small an angle (α) between the plane of the parent material surface and a plane tangential to the weldrun surface at the toe of the weld

|

|

| 5 |

5052 |

Incorrect weld toe radius |

Too small a radius (r) at the toe of the weld |

|

| 5 |

5061 |

Toe overlap |

Toe overlap at the weld toe |

|

| 5 |

5062 |

Root overlap |

Root overlap at the weld root |

|

| 5 |

5071 |

Linear misalignment between plates |

Pieces are plates |

|

| 5 |

5072 |

Linear misalignment between tubes |

Pieces are tubes |

|

| 5 |

508 |

Angular misalignment |

Misalignment between two welded pieces such that their surface planes are not parallel or at the intended angle

|

|

| 5 |

5091 |

Sagging in the horizontal position |

Sagging in the horizontal position |

|

| 5 |

5092 |

Sagging in the flat or overhead position |

Sagging in the flat or overhead position |

|

| 5 |

5093 |

Sagging in a fillet weld |

Sagging in a fillet weld |

|

| 5 |

5094 |

Sagging (melting) at the edge of the weld |

Sagging (melting) at the edge of the weld |

|

| 5 |

510 |

Burn-through |

Collapse of the weld pool resulting in a hole in the weld

|

|

| 5 |

511 |

Incompletely filled groove |

Longitudinal continuous or intermittent channel in the surface of a weld due to insufficient deposition of weld filler material

|

|

| 5 |

512 |

Excessive asymmetry of fillet weld (excessive unequal leg length) |

Explanation not necessary |

|

| 5 |

513 |

Irregular width |

Excessive variation in width of the weld |

|

| 5 |

514 |

Irregular surface |

Excessive surface roughness |

|

| 5 |

515 |

Root concavity |

Shallow groove due to shrinkage of a butt weld at the root (see also 5013)

|

|

| 5 |

516 |

Root porosity |

Spongy formation at the root of a weld due to bubbling of the weld metal at the moment of solidification

|

|

| 5 |

517 |

Poor restart |

Local surface irregularity at a weld restart |

|

| 5 |

5171 |

Poor restart in the capping run |

Poor restart in the capping run |

|

| 5 |

5172 |

Poor restart in the root run |

Poor restart in the root run |

|

| 5 |

520 |

Excessive distortion |

Dimensional deviation due to shrinkage and distortion of welds

|

|

| 5 |

5211 |

Excessive weld thickness |

Weld thickness is too large |

|

| 5 |

5212 |

Excessive weld width |

Weld width is too large |

|

| 5 |

5213 |

Insufficient throat thickness |

Actual throat thickness of the fillet weld is too small |

|

| 5 |

5214 |

Excessive throat thickness |

Actual throat thickness of the fillet weld is too large |

|

| 6 |

600 |

Miscellaneous imperfections |

All imperfections which cannot be included in groups 1 to 5 |

|

| 6 |

601 |

Arc strike stray arc |

Local damage to the surface of the parent material adjacent to the weld, resulting from arcing or striking the arc outside the joint preparation

|

|

| 6 |

602 |

Spatter |

Globules of weld metal or filler metal expelled during welding and adhering to the surface of parent material or solidified weld metal

|

|

| 6 |

6021 |

Tungsten spatter |

Particles of tungsten transferred from the electrode to the surface of parent material or solidified weld metal

|

|

| 6 |

603 |

Torn surface |

Surface damage due to the removal by fracture of temporary welded attachments

|

|

| 6 |

604 |

Grinding mark |

Local damage due to grinding |

|

| 6 |

605 |

Chipping mark |

Local damage due to use of a chisel or other tools

|

|

| 6 |

606 |

Underflushing |

Reduction in the thickness of the workpiece due to excessive grinding

|

|

| 6 |

607 |

Tack weld imperfection |

Imperfection resulting from defective tack welding |

|

| 6 |

6071 |

Tack weld imperfection |

Broken run or no penetration |

|

| 6 |

6072 |

Tack weld imperfection |

Defective tack has been overwelded |

|

| 6 |

608 |

Misalignment of opposite runs |

Difference between the centrelines of two runs made from opposite sides of the joint |

|

| 6 |

610 |

Temper colours (visible oxide film) |

Lightly oxidized surface in the weld zone, e.g. in stainless steels

|

|

| 6 |

6101 |

Discolouration |

Visibly tinted surface layers in the weld metal and heataffected zone caused by the weld heat and/or by lack of protection, e.g. in titanium

|

|

| 6 |

613 |

Scaled surface |

Heavily oxidized surface in the weld zone |

|

| 6 |

614 |

Flux residue |

Flux residue that is not sufficiently removed from the surface |

|

| 6 |

615 |

Slag residue |

Adherent slag that is not sufficiently removed from the surface of the weld

|

|

| 6 |

617 |

Incorrect root gap for fillet welds |

Excessive or insufficient gap between the parts to be joined |

|

| 6 |

618 |

Swelling |

Imperfection due to a burning on welded joints in light alloys resulting from a prolonged holding time in the solidification stage

|

|